Houston’s Top Mold Design Service Providers

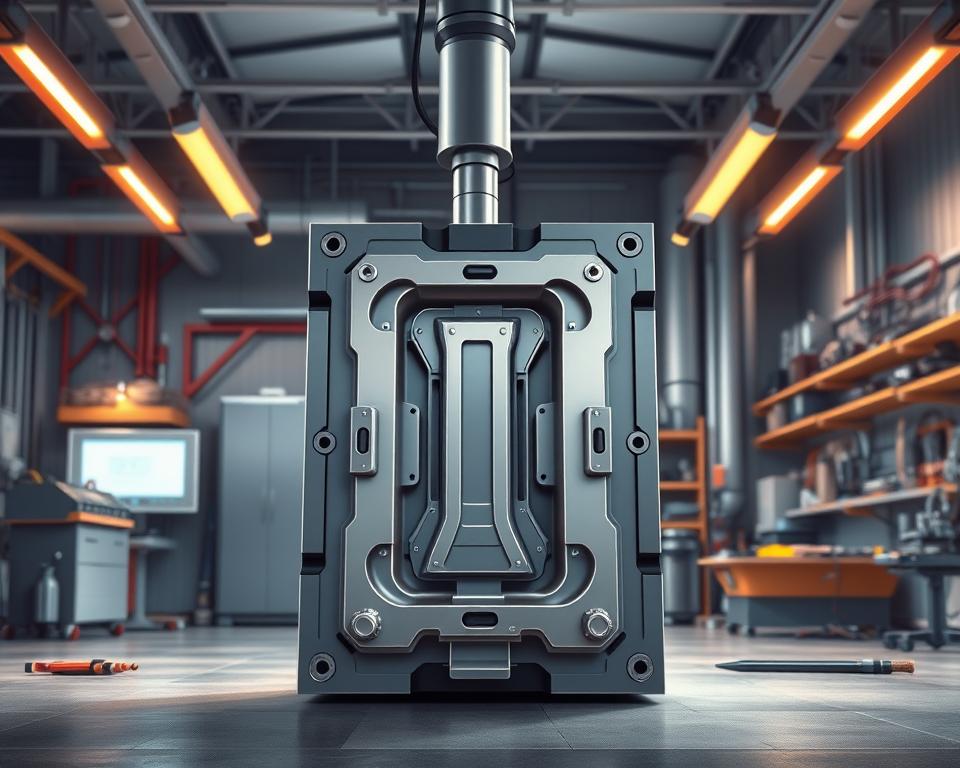

The global injection molded plastics market is set to hit $440 billion by 2025. These figures emphasize the critical role of professional mold design. They develop precision mold designs tailored to varied industries. In Houston, Lowrance Machine is a leading mold design company. Their expertise spans automotive, aerospace, and consumer-product mold design.

Leveraging CAD platforms and 3D-printing technology, Lowrance Machine. Their team ensures precision and efficiency in the molding process. Their seasoned experience and engineering prowess make them a dependable collaborator. Learn how their mold design Houston capabilities improve your initiatives and align with modern market requirements.

The Critical Role of Mold Design Services

Mold design services are vital in the manufacturing world, affecting product quality and operational efficiency. Effective mold design underpins both product function and lifespan. Companies that invest in expert mold design can cut production costs and improve quality standards.

Lowrance Machine showcases the value of working with seasoned professionals. They dive deep into client needs and work hand-in-hand to craft custom solutions. By employing cutting-edge methods like 3D modeling and CAD, they help businesses create molds that adhere to high standards.

Choosing top-notch mold design services boosts product performance and drives business success. Effective mold design leads to efficient manufacturing, giving companies a competitive edge in the market.

Houston Mold Design: Service Categories

At Lowrance Machine in Houston, you’ll find varied mold design solutions designed for every industry. Understanding each mold service type guides firms to the perfect choice for their tasks. Key categories include:

- Bespoke Mold Designs: Custom mold design solutions that cater to unique specifications and requirements.

- Prototyping: Early-stage mold prototyping to validate designs.

- Injection Mold Fabrication: Precision-engineered injection molds built to last.

- Advanced 3D Design: Utilization of advanced software to create detailed 3D models of molds, improving design accuracy.

- Mold Repair & Upkeep: Preventive and corrective mold maintenance to prolong tool life.

These services collectively enhance throughput, raise quality, and cut expenses. With clarity on service options, businesses can align mold solutions with their production goals.

Advantages of Expert Mold Design Partners

Choosing professional mold design experts brings numerous advantages to manufacturing processes. Gain improved accuracy, robustness, and throughput. Bespoke design drives superior product standards and uniformity.

Veteran designers inject invaluable process optimizations. They align molds with regulatory and bespoke requirements. Joint efforts spark innovation and extend product longevity.

Economical operations are a key perk. Cutting-edge methods slash material waste and speed up delivery. These improvements lead to better budgets and healthier profit margins. Fast-turnaround designs accelerate product launches.

Overall, professional mold services underpin manufacturing success. They dedicate themselves to streamlining operations and enriching output.

Innovative Techniques in Mold Design

Innovation has driven monumental shifts in mold design. Lowrance Machine leads the way with its cutting-edge mold design techniques. These methods enhance throughput and refine product excellence. Advanced mold design technologies play a significant role, streamlining the creation of unique molds and cutting down on time and costs.

Additive manufacturing shines by producing fast prototypes and intricate shapes. It cuts scrap dramatically versus conventional tooling. Simulation software allows designers to test and refine mold functionality virtually, improving both precision and efficiency.

In Houston, mold design experts are embracing these modern strategies. Companies are gaining a competitive advantage by leveraging digital design tools and advanced fabrication methods. They facilitate flexible, rapid-response mold development to satisfy diverse applications.

| Technique | Description | Benefits |

|---|---|---|

| Additive Manufacturing | Employs layer-by-layer building for quick mold production. | Shortens delivery times and cuts scrap. |

| Simulation Software | Visualizes mold design through computer models. | Boosts precision and refines function. |

| CAD Platforms | Leverages CAD for detailed mold engineering. | Enables tailored designs and quick edits. |

To Summarize

Expert mold design is essential for streamlined production and superior output in Houston. These services bring specialized know-how to overcome mold design hurdles. They ensure that each company’s unique needs are met, leading to better outcomes.

As a leader in accuracy and client partnership, Lowrance Machine stands out. The benefits of mold design, such as customized solutions and cutting-edge technologies, help manufacturers stay ahead in a fast-changing market. Engaging experts boosts standards and refines processes.

Choosing expert mold design services in Houston prioritizes both excellence and speed. Companies will satisfy market demands and sharpen their competitive edge. Leveraging professional mold design is crucial for success in a crowded industry.